Of course, like many watchmakers, I’ve serviced a few Omega Speedmaster Professionals over the years. I can say that it is always a treat. There are few watches that we can all collectively agree upon, have had such profound influence in watch history and collecting. I think every serious collector has at least one reference in their own collection (even the “Moonswatch” counts… sort of). This week I had the chance to work on two virtually identical Speedmasters. Both had a 77 million serial number which dates them both to 2005. This was a good year for the Speedmaster as it seems that they made over 5 million that year. So I guess it’s not that improbable that I would have two from that year.

The Speedmaster has a great origin story which I’d recommend reading about. The watch hasn’t changed very much since it went to the moon but it had a few faces and case designs before the “Professional”, as we know it, was created. Read about it here. These watches aren’t cheap and they never will be. As I keeping save up for one, the cost keeps going up. Feels kinda like a dog chasing his tail. Good thing I can service them. This way I have a deeper connection than even the owners have.

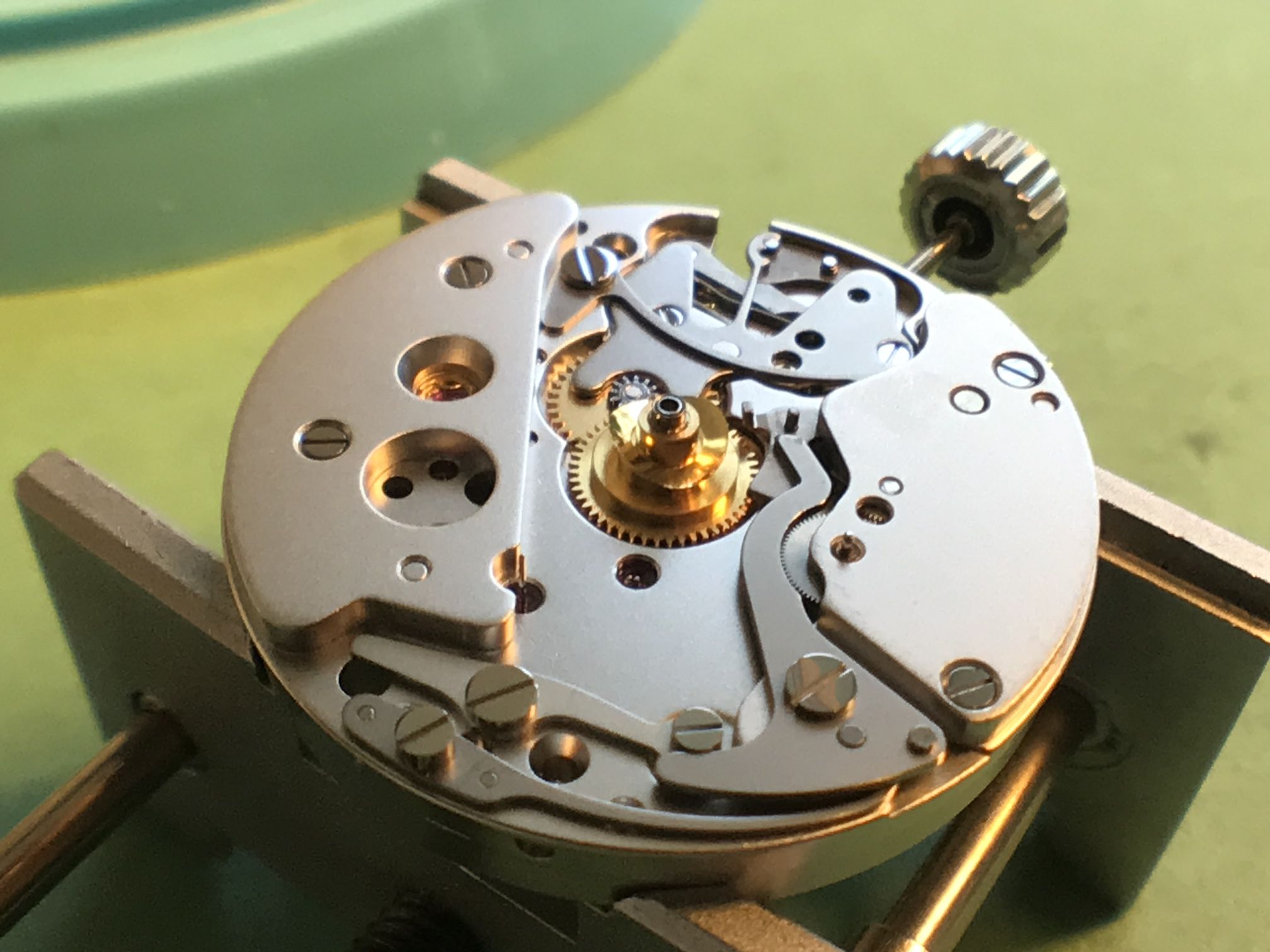

On to the watches. Both were in quite different condition. One needed quite a bit of adjusting. It had lots of end shake issues, worn bearings and needed a new bezel and crystal. The other had simply a broken mainspring and minimal wear. According to their owners, both had never been serviced so this is where I joined their stories. The 1861 movements were both in great cosmetic shape. The screw heads on both appeared untouched. This is pleasing, as it is the goal of every watchmaker (or should be) to leave no evidence of being inside a watch even after service. Leaving the screw heads pristine is a qualifier to identify those watchmakers who truly respect the craft, and those who just go through the motions.. These watchmakers may leave other parts of the watch different from how they were found. It’s really as easy as keeping your screwdrivers sharp.

Even though these watches are the exact same reference (145.0022) the only difference I noticed was the Omega logo on the chronograph runner bridge. The placement of the word “Omega” and grain were slightly different between the two. This tells me that the engraving machine had either been changed or adjusted during production.

Most likely is that they had several machines working in production that year. 5 million watches is a lot for one machine to handle and each may be adjusted differently. Sometimes you see these little variations even among the same reference. This makes the art of identifying counterfeit watches tricky. There may be something documented on this at the omega archives but that’s a really deep dive.

After service I had to take the opportunity to take a bunch of photos of the watches together. They may have met in the factory back in 2005 and probably had some catching up to do.