Even though I’ve been doing this trade for quite sometime, I keep learning about the many ways that have been invented to do basically the same thing, give us the time. The race in the past was to come up with the best and most accurate way of doing this. The history of timekeeping is a vast and very interesting one that really came to a pinnacle when quartz technology hit the market. This is the moment when innovators and scientists seeking accurate time technologies, simply dusted their hands and looked towards other mountains to climb because quartz regulation simply destroys all other forms of timekeeping. But there was a brief moment before this “quartz revolution” when many different and new innovations were flooding the market. One of them is the tuning fork.

This is the story of my journey with the Accutron and the tuning fork technology. Now, I’m not going to give you a history lesson on this technology but if you’re interested there are many resources out there. Check this one out. It was only produced for a few years in the 60s and quickly fell into obscurity in the 70s. The frequency of the tuning fork sits around 300hz (depending on the model) and this was far superior to the modest 5hz (give or take) that the Swiss lever escapement gives. Of course this pales in comparison to quartz, which runs at a blistering 32,768hz!! Now who can compete with that? Not the tuning fork apparently.

Today, the Swiss lever escapement has strangely survived the quartz era and is seen in most of the current mechanical watches on the market. Brands like Rolex, Seiko, most of the Swatch group and Richmont group brands, and many others use some form of it. What is interesting is that no one has taken up the baton to use tuning fork technology in modern times. Why has the Swiss lever seen such success but the tuning fork has drifted away? To be found only in the nostalgic hearts of us watch enthusiasts. In watchmaking school, the subject was barely explored and when I took on the task of learning how to service them, it was a lonely place and finding experts and technical assistance was challenging. But once I got some questions answered and some guidance and experience, I’ve found these watches and this technology pretty fricken cool and exciting.

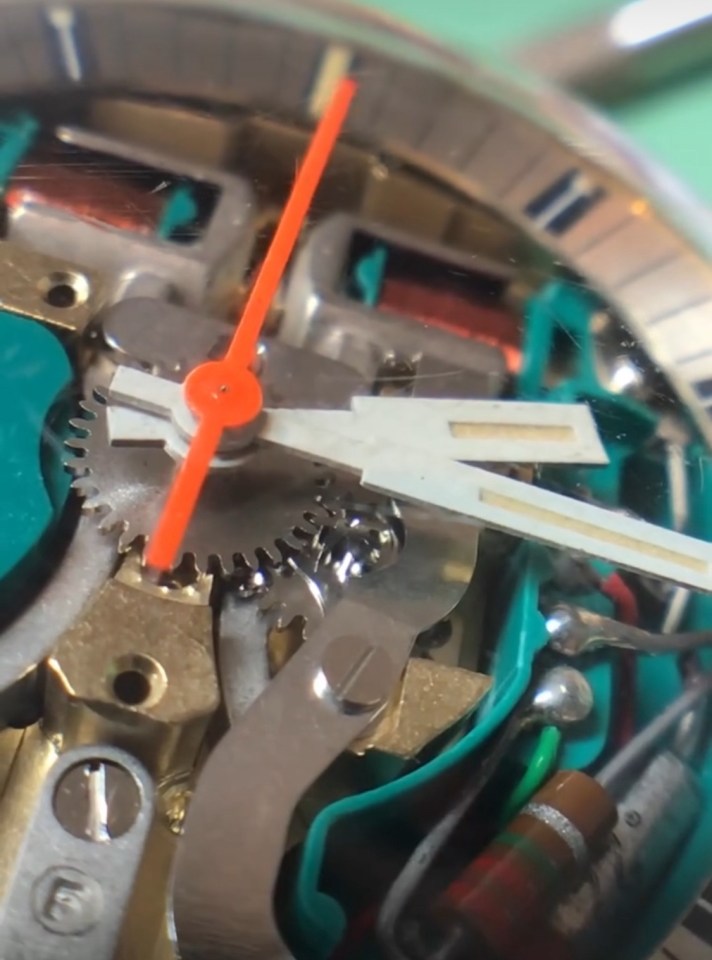

It’s always about the regulator. From the pendulum to the quartz crystal, this is the thing that vibrates and is measured and translated into timekeeping. The regulator of the Bulova Accutron and the Omega F300 is the tuning fork. As it vibrates back and forth at 300hz it pushes two very small jewels on the end of two very tiny rods to advance a wheel with 300 very tiny teeth to rotate once a second. This drives the gear train and thus the time. Simple right? (wink)

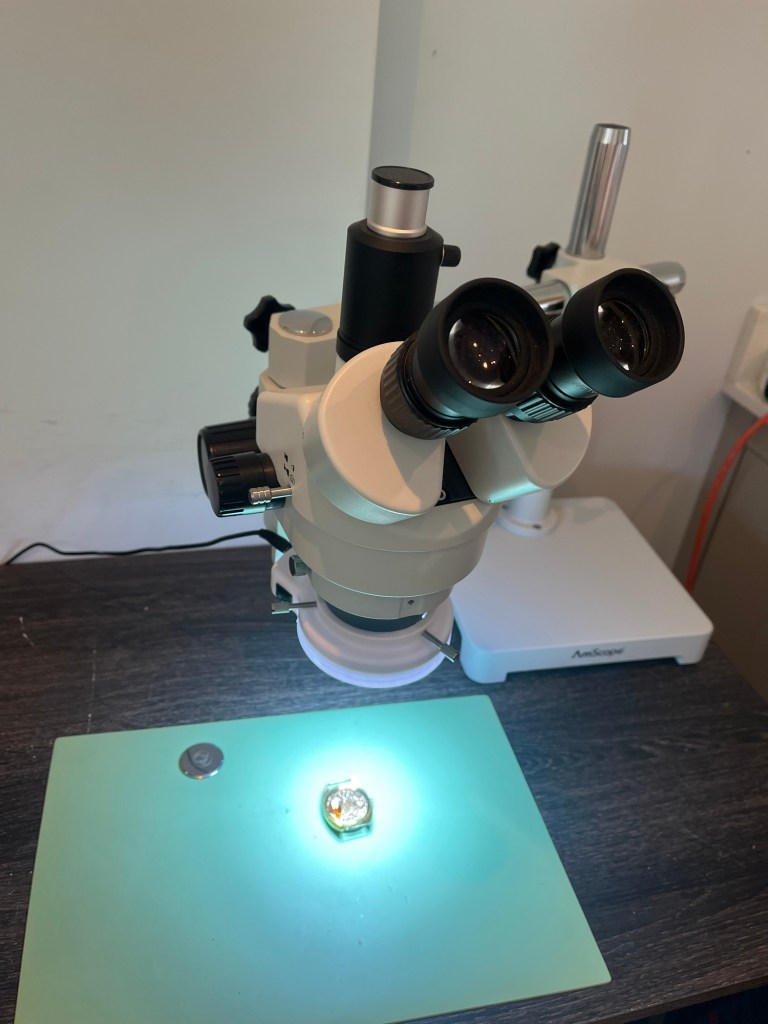

The first tool I bought so that I could work on these was my stereo microscope. This was a game changer as I am now able to see the indexing mechanism clearly and make the necessary adjustments. I usually use a 5times loope for my watch servicing but this microscope gives me 45 times magnification. Honestly, it feels like cheating and now I use it often on many of my other jobs. Now that I understand how this technology works and how to make adjustments, servicing the rest of the movement is like all the other jobs I take on. The cleaning, adjusting, proper lubrication, regulating etc, is like a walk in the park. It’s finding parts that is tricky. I have built a contact base of parts supply houses and other watchmakers who have some of these parts but they are often very expensive. I’d love to see someone come up with a new version of this. It sure would make finding parts easier if they could make them new again. If the Swiss lever can survive, I bet the tuning fork could capture the imagination of the watch lover and be the next obsession for collectors.

.